Showroom

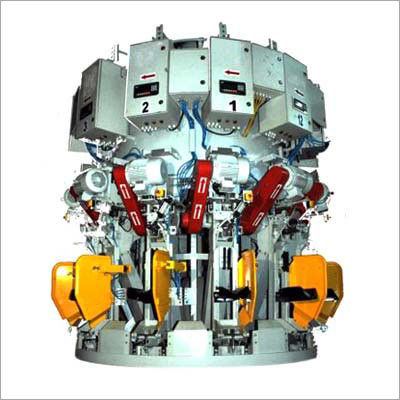

Rotary Packing Machines, like those used in cement packaging, employ rotary technology for precise filling and sealing. Their compact design optimizes floor space. Equipped with automated features, they ensure efficient operations. Versatile and reliable, they cater to various bag sizes and materials, enhancing productivity in industrial settings.

Stationary Packing Machines, like those utilized in cement packaging, offer robust solutions for accurate bag filling and sealing. Their stationary design ensures stability during operation, enhancing reliability. Equipped with advanced controls and sensors, they maintain precision and efficiency, making them essential for industrial packaging requirements.

A Cement Packing Plant integrates components like the Packing Machine Controller, Impeller Blade, and Pneumatic Flow Control Gate for efficient operations. Utilizing advanced technology, these plants streamline packaging processes, ensuring accuracy and consistency. Their robust design and automated features optimize productivity, making them essential for large-scale cement packaging operations.

A Loading Belt Conveyor, constructed with a 10-12mm thick rubber belt, is heat-resistant and suitable for temperatures from -10 to 80 degrees Celsius. With an 18-meter length, it efficiently transports materials, accommodating various packaging types like rolls. Its sturdy design and heat resistance ensure reliable performance in diverse industrial settings.

A Loading Belt Conveyor, crafted from durable rubber with a thickness of 10-12mm, is heat-resistant and suitable for temperatures from -10 to 80 degrees Celsius. Spanning 18 meters, it efficiently transports materials, accommodating various packaging types like rolls. Its robust design ensures reliable performance in industrial settings.

A Silo Extraction System utilizes developed technology to efficiently extract materials from storage silos. Its design comprises mechanical components like screws or pneumatic systems, guaranteeing seamless material discharge. These systems provide reliable operation, minimizing downtime and optimizing material handling processes in industrial settings.

The Silo Feeding Extraction System, with a capacity of 100-300 tons, is tailored for storing cement in vertical silos. Featuring a container length of 12-17 meters and a diameter of 3500 mm, it efficiently manages material flow. This system ensures consistent and reliable extraction, vital for uninterrupted industrial operations.

A Wagon Loading Machine utilizes cutting-edge technology for efficiently loading bulk materials onto railway wagons. Its design comprise conveyor belts or telescopic chutes, facilitating seamless loading operations. They are structured for durability and reliability, guaranteeing rapid and precise loading while optimizing logistics in industrial transportation processes.

A Pneumatic Cut Off Gate, crafted from selected grade of mild steel, operates with semi-automatic automation grade. Utilizing pneumatic technology, it controls material flow with precision. Its design incorporates a gate mechanism controlled by compressed air, ensuring efficient cutoff of material streams. They offer reliability, convenience of operation, and enhanced safety in industrial material handling usages.

A Spiral Chute is designed for efficiently transporting materials downward in a spiral motion. Utilizing gravity, it smoothly guides items from higher to lower levels. Its design has a helical-shaped trough with a smooth interior surface, guaranteeing gentle and controlled descent of materials. They are compact, versatile, and perfect for bulk material handling usages.

The Counter Guide Assembly is a component utilized in varied machinery setups, offering support and alignment for moving parts. Its design has a sturdy frame with adjustable features for ensureing precise positioning. This assembly increases stability, decreases vibration, and improves overall efficiency in varied industrial usages needing accurate alignment.

The Automatic Screw Sampler, constructed from mild steel, efficiently collects screw samples for analysis. With a capacity of 65 kgs, and a length of 400 mm, it accommodates screws ranging from 35mm to 50.8mm in outer diameter and thread sizes of 2-20mm. This device ensures accurate and consistent sampling in industrial settings.